Steam turbine inspection is a methodical procedure. It’s designed to assess the state and functionality of these vital parts in the production of electricity.

Frequent inspections accomplish a number of goals. This includes spotting any problems and evaluating the integrity of parts. Also, guaranteeing adherence to operational guidelines.

Reliability can be improved. Unplanned downtime can be avoided with a systematic inspection schedule.

Regular assessments enable the early identification of damage or wear. Since this might not be noticeable during regular operation.

Visual evaluations, vibration analysis, and NDT are frequently used in turbine inspection procedures. These offer insightful information about the unit’s operation and system efficiency.

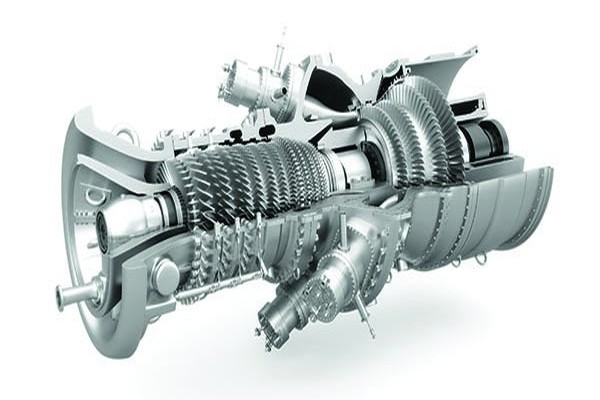

A steam turbine: what is it?

A heat engine that transforms pressurized steam’s heat into mechanical or rotary energy. This powers an electrical generator to provide electricity.

It functions similarly to an advanced windmill. In which high-temperature, high-pressure steam presses against shaft-mounted bladed wheels. Thus, causing them to spin quickly.

These are the main components of most thermal power plants. Such as fossil fuel, nuclear, and geothermal. Their constant rotation powers the generator.

How It Operates

- Steam Generation: A boiler produces superheated, high-pressure steam by heating water utilizing a fuel source. This includes gas, coal, nuclear, or solar energy.

- Energy Conversion: The vapor is directed toward the blades via nozzles.

- Rotation: The rotor spins as a result of the expanding force pushing the blades. It is then transforming the potential power into kinetic energy.

- Electricity Generation: An electric generator is attached to the rotating rotor. It transforms its physical rotation into electrical energy.

- Exhaust: Vapor leaves the unit at a reduced temperature and pressure. It’s frequently condensing back into water to start the cycle over.

Components That are Affected and Inspected

An examination usually looks at the following important parts:

- Rotors: Since undiagnosed problems might result in failures – look at https://turbinelogic.com/enc/combined-cycle-block/steam-turbine/high-pressure-turbine/rotor-shaft-c, for instance. So, it’s crucial to check for cracks or wear indicators.

- Blades: This must be inspected for wear, damage, or erosion because they operate in harsh environments.

- Bearings: Examinations look for indications of overheating, alignment, and sufficient lubrication.

- Seals: To stop leaks, which can reduce efficiency, gland seals alongside other sealing elements are crucial.

By ensuring that every component functions within acceptable bounds. This comprehensive inspection lowers the possibility of unanticipated failures.

First Warning Indications

A number of early warning indicators that call for a check should be recognized by operators. Timely interventions can result from monitoring particular parameters, such as:

- Elevated levels of Vibration: Unusual vibrations could indicate bearing wear, imbalance, or misalignment.

- Modifications to Performance Metrics: Unexpected fluctuations in vapor flow or a drop in efficiency may indicate underlying problems.

- Unusual Noise: During operation, sounds like grinding could be a sign of mechanical system issues.

- Leaks: Leaks at joints or seals should be fixed right away because they can cause performance problems.

Operators can look into and address such issues before they escalate by monitoring these signs.

Common Root Causes

Checks are required for a number of reasons. Effective maintenance plans require an understanding of these:

- Functional Wear and Tear: The cyclic forces involved in turbine operation cause components to deteriorate.

- Environmental Factors: Wear can be accelerated by variations in temperature, humidity, and particulate matter.

- Inadequate Maintenance: The necessity for a checkup may be accelerated by inconsistent maintenance procedures.

- Unexpected Loading Conditions: The unit may be stressed by variations in operational demands.

The unit’s longevity and dependability can be improved by addressing these issues – look at this to read further.

Diagnosis and Research

During inspections, a variety of techniques and instruments may be used in the diagnosis and research process. Important methods consist of:

- Visual Checks: Regular examinations for surface damage, corrosion, or physical anomalies.

- Accelerometers are used in vibration analysis to evaluate vibration patterns and detect imbalance or misalignment.

- Non-destructive testing or NDT: Magnetic particle or ultrasonic testing can find interior defects. Without causing component damage.

- Thermal Imaging: Early problem detection may depend on locating hot spots.

With the use of these diagnostic instruments. Engineers may precisely evaluate each component’s state. Thus, guiding maintenance plans.

Corrective and Mitigation Measures

It’s crucial to determine and put into practice suitable mitigation and corrective measures after an examination. Some tactics could be:

- Repairing or replacing broken components as soon as they are found during examination.

- Making sure that parts are correctly aligned to reduce vibration problems.

- Preventing premature wear by optimizing lubrication systems.

- Adapting operational practices to lessen strain.

Operators can extend the life of their units by taking decisive action in response to inspection findings.

Effects on Risk and Plant Performance

Frequent checkups have a big impact on risk reduction and overall plant performance. By guaranteeing ideal operating, proactive evaluations boost production and dependability. Furthermore, resolving problems before they arise might save money on unanticipated outages.

Additionally, regular examination procedures reduce the safety hazards related to operations. Operators can protect people and equipment by implementing timely actions. Especially when they have a thorough grasp of the state of the unit.

If you want to achieve exceptional performance in operation inside power plants. Know that it requires a strong checkup methodology.